Fold, Bind, Bank: Turn Tie-Dye Mastery into a Profitable Apparel Drop in 7 Days

Fold, Bind, Bank: Turn Tie-Dye Mastery into a Profitable Apparel Drop in 7 Days

Fold, Bind, Bank: Turn Tie-Dye Mastery into a Profitable Apparel Drop in 7 Days

Why Tie-Dye Now

Color is political. It can soothe. It can rally. In markets from Lagos to London, a color-soaked comeback is pushing micro-drops to sell out in hours. Modern palettes feel intentional, not chaotic. Think earthy neutrals that whisper luxury, sorbet pastels that soften streetwear silhouettes, and ice-dye marbling that looks like aerial photos of the Sahara during harmattan. Tie-dye is not a fad. It is a language that speaks directly to personal identity, cultural pride, and the need for handmade authenticity in a world that still feels mass produced.

Micro-drops fit the rhythm of mobile commerce. Ten pieces at a time, two colorways, photographed beautifully, launched with a countdown. The scarcity is honest. You made these with your hands. That trust, paired with modern palettes, is why small dye studios are moving units and building communities rather than chasing faceless scale.

How this differs from our other maker playbooks

If you have studied screen print guides or Ankara sourcing roadmaps, this playbook is different. It centers resist dyeing, hands-on chemistry, and cultural lineage. It is a seven day sprint that balances historical respect with agile e-commerce tactics. No repeats. New angles. Fresh palette.

Respecting Roots

Adire, from the Yoruba cities of Abeokuta and Ibadan, is a deep well of technique and meaning. Women used raffia ties, stitch resists, and cassava starch to resist indigo on cotton. Patterns signaled social networks, wisdom, and status. During colonial rule, Adire traders helped fund community life, sent children to school, and confronted unfair taxation. In Japan, Shibori developed over centuries into a refined vocabulary of compression, stitching, and pole wrapping. Indigo was common, geometry was precise, and the work was revered as craft and art.

To be inspired without appropriating, do three things. Name the source in your copy. Use respectful language that credits Adire and Shibori as lineages. If you quote names, cite them. Do not market Adire as a personal invention. If you adapt a motif, explain the adaptation and avoid sacred symbols you do not fully understand. Consider directing a percentage of a special-edition run to a textile education fund or to a museum program that preserves dye archives.

A brief story from history

In 1947, in Abeokuta, market women organized under the Abeokuta Women’s Union led by Funmilayo Ransome-Kuti. Many were Adire dyers and traders. They climbed the palace steps and demanded an end to abusive flat taxes that bled their livelihoods. Cloth may seem soft. Power is not. The protests lasted months, forced negotiations, and reshaped local governance. When you lift a bucket of dye and bind a spiral, you are not just making patterns. You are touching a history of women who knew how to turn craft into leverage.

Startup Kit on a Budget

You can launch with 80 to 150 dollars if you buy smart.

- Blanks: 100 percent cotton tees, hoodies, onesies, tote bags, bandanas. Avoid blends for your first drop.

- Dyes: Fiber reactive dyes like Procion MX. Choose three to five modern colors.

- Fixer: Soda ash for the pre-soak.

- Urea: Optional. Helps dissolve dye for smoother applications in heat or low humidity.

- Tools: Squeeze bottles, rubber bands or cord, zip bags, plastic wrap, drying racks.

- Safety: Nitrile gloves, particulate mask or N95 for powder handling, apron, eye protection.

- Workspace: Plastic table cover, buckets, measuring spoons, a simple wire rack to keep fabric off pooled dye.

Keep receipts. Track cost of goods from day one.

Safety and Setup

This is kitchen chemistry with commitment. Treat it with respect.

- PPE and ventilation: Wear gloves and a mask when handling powder. Work with a fan or open window. Avoid eating in the dye zone.

- Dye chemistry basics: Fiber reactive dyes form covalent bonds with cellulose fibers. That is why cotton and rayon thrive and polyester does not. You raise pH with soda ash, then allow time and warmth for the reaction to finish.

- Cure time and temperature: Aim for 21 to 27 degrees Celsius. Bag and cure 12 to 24 hours. Warmer rooms cure faster. Do not rush.

- Water and waste: Keep ice dye rigs over trays so meltwater is easy to collect. Strain solids. Neutralize high pH water with a little white vinegar before disposal, then follow local regulations. Never pour dye slurry into storm drains. Reuse buckets. Keep a dedicated sink if possible.

- Stain-proofing: Line your table and floor with plastic or old shower curtains. Keep paper towels ready. Label all bottles.

Fabric Prep

Great color starts with clean fiber.

- Scour or pre-wash: Hot wash blanks with a small amount of detergent. No softeners. Rinse well.

- Soda ash soak: Mix 1 cup soda ash into 1 gallon of warm water. Stir until dissolved. Soak garments 15 to 20 minutes.

- Wring to damp: Squeeze out excess. You want damp, not dripping.

- Organize: Sort by size. Add hang tags now if they attach away from dye zones. Keep a checklist so no blank gets lost in the pile.

Pattern Recipes

Your hands are the algorithm. Respect the steps, then riff.

Spiral Galaxy

- Center pinch. Place two fingers at the center point you want to showcase.

- Twist clockwise while smoothing fabric into a neat disk. Keep it flat to avoid bulky ridges.

- Pie-wedge bands. Use rubber bands to divide the disk into 6 to 8 wedges.

- Color sequence. Place complementary colors in alternating wedges. Leave one wedge white if you want air in the pattern.

- White-space control. Tight twists yield more white lines. Looser twists create broader color bands.

Accordion and Stripes

- Precise pleats. Fold fabric back and forth in even pleats. Use a ruler for crisp lines.

- Clamp options. Add binder clips or wood blocks to create sharp resist edges.

- Two-tone gradients. Load one side with a darker tone, the other with a lighter tone from the same family. This reads sleek and modern.

Bullseye and Concentric Rings

- Mark the center. Tie a small knot where you want the bullseye to bloom.

- Spaced ties. Add ties every 2 to 4 inches as you move outward. Mix spacing to create rhythm.

- Dye with intention. Alternate colors between rings to avoid muddy overlaps.

Cloud and Scrunch

- Organic texture. Scrunch fabric loosely without hard folds. Bind gently with a few loose bands.

- Low-mud placement. Keep neighbors friendly on the color wheel. Think peach next to lavender, olive next to sand.

Ice Dye Marble

- Rack setup. Place damp fabric on a mesh rack above a tub. Pile ice or snow on top.

- Powdered dye on ice. Sprinkle dye powder lightly. Less is more. Watch as meltwater drags pigment down for marbled veins.

- Slow-drip magic. Leave it undisturbed. Twelve to eighteen hours. Patience yields complexity.

Shibori-Inspired Arashi

- Pole wrap. Roll fabric around a PVC pipe or broom handle.

- Diagonal compression. Wind string diagonally and push fabric down to compress.

- Monochrome looks. Use indigo or a single hue with dilution steps for subtle tonal bands.

Fixing and Finishing

Your future reviews live here.

- Bag and cure. Seal each piece in a bag or plastic wrap. Wait 12 to 24 hours.

- Cold rinse. Rinse in cold water until almost clear. Remove ties gently.

- Hot wash. Wash hot with textile detergent. Rinse again.

- Colorfastness test. Rub a white cloth on the damp garment. If color transfers, repeat washing.

- Finish line. Steam or press lightly. Attach size tags and care cards. Photograph while pieces are pristine.

Care card copy tip: Cold wash with like colors. Hang dry for longevity. Do not bleach. Expect artful variations.

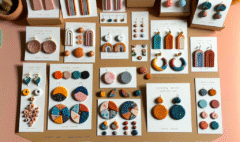

Design Your 10 Piece Starter Drop

Make a small orchestra, not a noisy crowd.

- 3 tees

- 2 tote bags

- 2 bandanas

- 1 hoodie

- 1 sock set

- 1 baby onesie

Create two cohesive colorways. Example: Desert Dawn with sand, clay, olive. And Lagoon Night with indigo, teal, steel. Edition number every piece. Handwrite 1 of 10 to reinforce scarcity and care.

Visual Branding and Story

Build a mood board around touch and sky. Choose a name that breathes. Draft a logomark that fits on a 2 inch sticker and on a hoodie tag. Define a palette that mirrors your drop. Write copy that says what inspired you and who the tradition belongs to. Sam

ple copy: Inspired by Yoruba Adire resist dye, made by hand in Accra. We thank the artists and archives that preserve these techniques.

Make only sustainability claims you can prove. If you use recycled mailers, say so. If you save water by batching rinses, quantify it.

Photography That Sells

Your phone is enough if your light is honest.

- Window light. Shoot near a window with indirect light. Avoid mixed color temperatures.

- White foam board reflectors. Two boards at a 90 degree angle bounce light into shadows.

- Flatlays and on-body shots. Tell the garment story and the human story. Size inclusive models matter.

- Macro texture details. Let viewers see the grain of the cotton and the bloom of the dye.

- Process reels. Ten to fifteen second clips of ties, powder shakes, rinse reveals. Caption with tips.

Pricing and Margins

Aim for 60 to 70 percent gross margin to fund growth.

Sample COGS for a tee

- Blank 100 percent cotton tee: 3.80 dollars

- Dye and soda ash allocation: 0.80

- Gloves, ties, consumables: 0.40

- Water and energy estimate: 0.35

- Packaging, sticker, care card: 0.85

- Total COGS: 6.20

Price at 28 to 38 dollars depending on brand strength and market. At 34 dollars, gross margin is about 81.8 percent minus platform fees. After fees and marketing, you land in the 60 to 70 percent zone.

Tiered pricing

- Tees 28 to 38

- Bandanas 12 to 18

- Totes 22 to 32

- Hoodie 58 to 88

- Sock set 16 to 24

- Onesie 18 to 26

Bundles lift average order value. Example, Tee plus bandana bundle at 44, perceived value 52.

Use a simple spreadsheet. Track material pulls per item. Review weekly.

Sales Channels

- Etsy quick start. Fast setup, built-in audience. Use tags like ice dye, Adire inspired, cotton.

- Instagram Shop. Product tags in posts and reels. Build community in comments.

- TikTok Live demos. Show the fold. Answer questions. Launch with a countdown.

- Craft markets. Touch is conversion. Bring a small rack and a mirror.

- Wholesale linesheet. Include two colorways, MOQ 25 per style, lead time 3 to 4 weeks. Offer reorder windows.

- Consignment pros and cons. Exposure is high. Cash flow is slow. Cap consignment at 20 percent of your production.

The 7 Day Launch Plan

Day 1. Research and palette lock. Build the mood board. Name the drop. Order or pull blanks. Mix test swatches for Desert Dawn and Lagoon Night. Decide on five patterns for the collection.

Day 2. Pre-wash and scour all blanks. Make soda ash bath. Soak, wring to damp. Organize sizes and tag blanks. Set up a clean, safe dye station.

Day 3. Dye day one. Execute Spiral, Cloud, and Accordion designs in Colorway A. Bag and cure. Journal your exact steps.

Day 4. Dye day two. Execute Bullseye, Ice Marble, and Arashi in Colorway B. Bag and cure. Start writing product copy while you wait.

Day 5. Rinse and wash. Cold rinse to near clear. Hot wash with textile detergent. Steam and press. Shoot flatlays, on-body, and macros. Cut your process reels.

Day 6. Listings and teaser. Upload photos, write SEO-rich titles and descriptions, set inventory numbers by size. Send email teaser and post a 24 hour countdown across platforms.

Day 7. Drop day. Go live with a short dye demo. Pin the shop link. Answer DMs fast. Offer a limited bundle for the first 20 orders. Celebrate each sale in Stories. Close the day with a thank you and a restock survey.

Packaging and Unboxing

- Recycled mailers. Compostable where possible.

- Tissue and brand sticker. Keep it simple and consistent.

- Care card. Include washing instructions and a short cultural note with sources.

- QR code to a 60 second care video. Reduce returns and earn trust.

- Lightweight shipping classes. Keep parcels under key weight thresholds to save costs.

Customer Care and Retention

- Sizing exchanges. One free exchange in 14 days if stock allows. Clear rules avoid friction.

- Care education. Pin a care guide on Instagram. Link it in post purchase emails.

- Repair and re-dye service. Offer a fix for faded or stained pieces for a small fee. Craft meets circularity.

- VIP list. Early access to drops for repeat buyers.

- Review capture. Automate a 7 day post delivery email with a gentle ask and a photo prompt.

Scale Without Burnout

- Batch dyeing. Group by colorway and technique. Reduce setup time.

- Color SOPs. Write recipes by grams per bottle and dilution ratios. No guessing.

- Rinse station upgrades. Use a hose with spray nozzle, mesh racks, and laundry bags to handle volume.

- Helpers. Train a rinse assistant or a folder. Document every step.

- Wholesale reorders. Offer 10 percent off for prepayment.

- Seasonal capsules. Small, story driven releases. No empty inventory.

- Team workshops and DIY kits. Teach r

esist dye to local companies and schools. Sell branded kits with clear safety notes.

Legal and Environmental

- Registration. Register your business and choose a tax structure in your country.

- Labeling. Include fiber content, country of origin, and care symbols. Follow local laws.

- Sales tax and VAT. Understand thresholds for marketplaces and cross border sales.

- Studio safety. First aid kit, MSDS sheets for dyes, proper ventilation.

- Water and dye disposal. Follow municipal rules. Neutralize, filter, and never dump solids.

Troubleshooting

- Muddy colors. Cause, overlapping complementary colors or over saturation. Fix, use analogous neighbors and apply less dye. Add more white space.

- Under-dyeing. Cause, not enough dye or too dry fabric. Fix, ensure dampness and increase dye load slightly.

- Bleeding after wash. Cause, short cure time or weak washout. Fix, cure longer, hot wash with detergent, and retest.

- Harsh lines. Cause, tight ties and fast application. Fix, loosen binds slightly, add small dips of water to soften transitions.

- Uneven saturation. Cause, thick folds or blocked flow. Fix, work dye into creases, flip pieces while applying dye, use racks to avoid pooling.

Action Checklist

- Materials to buy: Cotton blanks, Procion MX dyes, soda ash, urea, squeeze bottles, ties, rack, PPE, mailers, tissue, stickers, care cards.

- Patterns to master: Spiral Galaxy, Accordion Stripes, Bullseye Rings, Cloud Scrunch, Ice Marble, Arashi Pole Wrap.

- First 10 SKUs: 3 tees, 2 totes, 2 bandanas, 1 hoodie, 1 sock set, 1 onesie. Two colorways.

- Photo shot list: Flatlay front and back, on-body full shot, macro texture, process still, bundle shot.

- Launch timeline: Seven days as detailed above. Put it on a calendar.

- Week one revenue target: 650 to 1,200 dollars depending on price points and sell through. Track daily. Learn fast.

A living story from the studio floor

In the courtyard behind a tiny shop in Oshodi, a young designer named Ireti pulls on gloves and tips blue powder into a bottle. Her aunt once dyed cloth near the Ogun River. Migration pulled the family toward the city. She remembers the smell of starch on a hot morning, the laughter of women leaning over vats, the shock of first seeing a dress turn sky from white to midnight. Today, her phone rests on a stack of books as she streams a short live. A viewer in Nairobi asks about care. A buyer from Leeds wants a size chart. Ireti nods, ties a spiral, explains Adire and where she learned her folds, and tells the story of Funmilayo and the palace steps. She smiles as orders ping like drumbeats. Color can be a livelihood. Color can be memory. Color can be a small, serious business run with care.

Your move

Will you fold your first spiral and put a date in the calendar, or will you scroll past your own opportunity again? Pick a palette, pick a pattern, and begin.

Sources and further reading

- Judith A. Byfield. The Great Upheaval of 1947 and the Abeokuta Women’s Union. In The Bluest Hands: A Social and Economic History of Women Dyers in Abeokuta, Nigeria, 1890–1940. Heinemann, 2002.

- National Museum of African Art, Smithsonian Institution. Adire cloth collections and essays. https://africa.si.edu

- British Museum Collection Online. Adire textile examples and descriptions. https://www.britishmuseum.org/collection

- Yoshiko Iwamoto Wada, Mary Kellogg Rice, and Jane Barton. Shibori: The Inventive Art of Japanese Shaped Resist Dyeing. Kodansha International, 1983.

- UNESCO Courier. Indigo, a blue thread tying cultures. Selected articles on dye heritage. https://en.unesco.org/courier

- Dharma Trading Co. Procion MX technical notes and safety data sheets. https://www.dharmatrading.com

- EPA guidelines on household hazardous waste and local disposal rules for small craft operations. https://www.epa.gov/hw/household-hazardous-waste-hhw

Continue