From Indigo to Income: Master Adire Resist-Dye and Turn Textiles into a Thriving Brand

From Indigo to Income: Master Adire Resist-Dye and Turn Textiles into a Thriving Brand

From Indigo to Income: Master Adire Resist-Dye and Turn Textiles into a Thriving Brand

THE STORY AND THE SPARK: WHY ADIRE, WHY NOW, AND HOW ARTISTRY BECOMES A BUSINESS

Adire is Yoruba ingenuity rendered in blues that breathe. It began as everyday fabric and rose to ceremonial art, a language in cloth. Today, it is also a viable business that honors heritage while meeting modern demand for slow-made goods. In a world full of printed look-alikes, hand-resist indigo commands trust and price. If you are looking to build a brand with cultural depth, tactile beauty, and clear margins, Adire gives you a blueprint.

A quick compare so we avoid overlap with other African crafts you may already know. Unlike Kente, which builds pattern through weaving on the loom, Adire builds pattern by blocking dye on finished cotton. Unlike Malian bogolanfini mudcloth that fixes color with iron-rich mud, Adire leans on indigo chemistry, oxygen, and time. The craft is a cousin to Japanese itajime folding, yet its soul is Yoruba, steeped in names, stories, and market wisdom from Abeokuta to Osogbo.

CULTURAL ROOTS AND RESPECT: YORUBA ORIGINS, NAMING PATTERNS, AND ETHICAL APPRECIATION

Adire was perfected by Yoruba women, especially Egba dyers who traded at Itoku Market in Abeokuta. Motifs have meaning. Olokun speaks to the depth of the sea deity, Iresi hints at grains and abundance, Oniko points to raffia ties that create constellations. Honor these names, credit Yoruba origins, and avoid claiming invention. If you borrow sacred symbols or shrine-related imagery, seek guidance and permissions. Build reciprocity. Donate a percentage to community-led textile trainings or apprentice programs, and feature Yoruba voices in your brand storytelling.

Human story. In the late twentieth century, artist and educator Nike Davies-Okundaye taught Adire techniques to hundreds of women, reviving livelihoods after economic downturns. Her workshops in Osogbo turned skill into income, proof that art and enterprise can walk together when culture leads the way.

TOOLS, MATERIALS, AND BUDGET

Start lean, then scale.

- Fabric: 100 percent cotton poplin or broadcloth, 4 to 6 yards to start

- Resist: raffia or strong thread, needles, starch options like cassava paste or rice starch, plastic sheets for stencils

- Indigo vat: natural indigo or synthetic indigo, soda ash or slaked lime, reducing agent like fructose or sodium hydrosulfite

- Hardware: buckets, measuring jars, pH strips or meter, stirring sticks, gloves, masks, clips, folding boards, clamps

- Workspace: racks or lines for drying, plastic sheeting for floors, labeled bins

- Branding: swing tags, woven labels, care labels, zip bags or recycled tissue

Entry budget estimate, 250 to 600 dollars, depending on vat type and initial fabric stock.

SAFETY AND WORKSPACE SETUP

- Ventilation: work outdoors or near an open window with a fan

- Skin protection: nitrile gloves, apron, closed shoes, optional safety glasses

- Masks: dust mask when handling powdered indigo or chemicals

- Spill control: plastic drop cloth, paper towels, baking soda for neutralizing small acidic spills

- Dye-waste management: keep separate containers for rinse water, let sediment settle, neutralize and oxidize before disposal according to local rules

DESIGN STRATEGY: FROM MOOD BOARD TO SWATCH

Collect references from Yoruba pattern lexicons, ocean ripples, cassava leaves, basket weaves, shell spirals. Build a mood board with five to seven motifs. Decide on repeats that look good at scarf scale and at yardage scale. Make ten small swatches before you commit to production. Document what works like a chef writing down a sauce.

RESIST TECHNIQUES OVERVIEW

- Oniko, tying with raffia or thread to form dots, rings, and clusters

- Alabere, stitch resist, fold, stitch, pull to pucker, then dye for feathery contours

- Eleko, cassava-paste stencil or freehand application, thick paste blocks indigo and keeps crisp edges

- Folding and clamping, itajime-style squares, diamonds, or stripes using boards and clamps for bold geometry

Blend techniques. Oniko halos inside Eleko borders, stitch resist across folded axes, layered looks create signature styles.

FABRIC PREP: CLEAN COTTON, CLEAN RESULTS

Scour the cotton. Hot water, a splash of soda ash, and a drop of detergent remove sizing. Rinse until water runs clear. Line dry, then press. Prepped fabric absorbs indigo evenly and stops surprises later.

MIXING THE PASTE: CASSAVA CONSISTENCY, STENCILS, AND DRYING

- Paste: sifted cassava flour with warm water to a yogurt-thick slurry. For extra body, add a teaspoon of rice starch per cup

- Stencils: cut from thin plastic sheets or old x-ray film. Simple motifs first, nested complexity later

- Application: squeegee or spatula through stencil, or freehand with a cone

- Drying: lay flat until fully dry, 6 to 24 hours depending on humidity. Dry paste should not transfer to your finger

BUILDING THE INDIGO VAT: REDUCTION, PH, FLOWER, FIXES

Choose your path.

- Natural fructose vat: indigo paste, warm water, lime to pH 9 to 10, fructose to reduce. Aim for a bronze surface bloom, called the flower, and a green-yellow liquid below

- Synthetic quick vat: indigo powder, soda ash to pH 10 to 11, sodium hydrosulfite to reduce. Maintain warmth around 35 to 45 Celsius, avoid splashing air

Troubleshooting muddy vats:

- If the liquid turns blue and lacks the bronze flower, it is over-oxygenated. Let it rest covered, then add a small dose of reducer

- If the vat smells sulfurous or the pH drops, adjust gently with lime or soda ash, test again

- If color is weak, check concentration first, reduction second, temperature third

Use a pH strip every session. Stir slowly, like folding batter, so you do not pull in air.

DYEING WORKFLOW: DIP-OXIDIZE CYCLES FOR DEPTH

- Wet the fabric evenly, then squeeze out excess

- Dip 1 to 3 minutes, lift slowly, allow drips back into vat

- Oxidize in air 5 to 10 minutes until green turns blue

- Repeat 4 to 12 dips for deeper blues, rest between dips to avoid fiber stress

- Keep notes, the fifth dip often gives rich mid-navy, the ninth goes near midnight

RINSE, REVEAL, AND FINIS

H

Remove ties, peel paste, celebrate the reveal. Rinse in cool water until mostly clear. Soak in a mild neutralizing bath, water with a little white vinegar or citric acid, then a final wash with pH-neutral soap. Line dry in the shade. Press with steam for a smooth hand.

QUALITY CONTROL: DETAILS THAT WIN RETURNS AND REVIEWS

- Edge finishing: overlock or zigzag edges before dye, clean hems after

- Seam tests: pull on seams of sewn goods. No puckers, no loose threads

- Crocking tests: rub a white cotton square on the dyed cloth, once dry and once damp, check for transfer. If transfer happens, add a final soap wash and extra oxidation time

- Care label standards: fiber content, country of origin, wash advice, and color bleed warning on the first wash

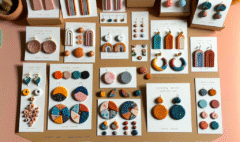

PRODUCT MENU: BUILD A LINE, SERVE A MARKET

- Scarves and bandanas for the wearable crowd

- Totes and zip pouches for daily use

- Cushion covers and table runners for home

- Yardage for designers who want authentic base cloth

Limit options early, keep inventory tight, retire patterns seasonally to maintain curiosity.

PRICING WITH PROFIT: COGS, LABOR, OVERHEAD, MARKUP, WHOLESALE

Know your numbers.

- COGS: fabric, dye, chemicals, paste, labels, packaging

- Labor: track making time per item, pay yourself a real wage

- Overhead: workspace rent, utilities, website fees, transport

- Markup: cost times 2.2 to 3.0 for retail, cost times 1.5 to 2.0 for wholesale

- Perceived value: hand, story, finish, and scarcity lift price honestly

Wholesale math matters. Price so wholesale covers cost and pays profit, not just cash flow.

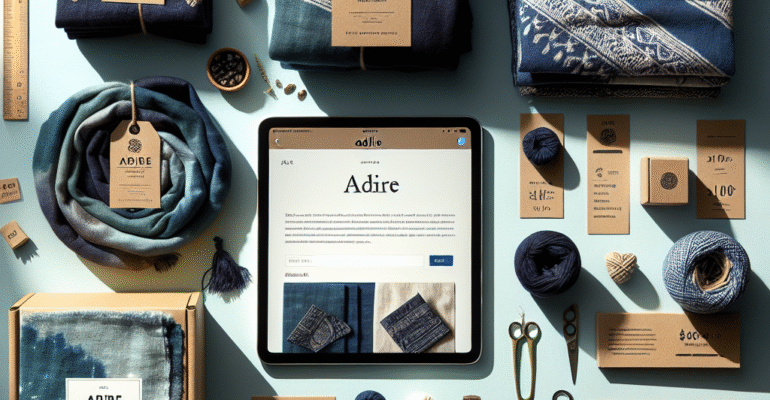

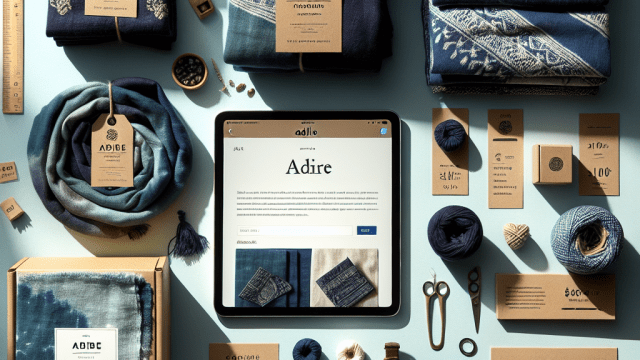

BRANDING THE STORY: NAME, LOGO, LABELS, PHOTOGRAPHY, PACKAGING

Choose a brand name that signals Yoruba roots with respect, or your own name if you are an outsider ally. A clean logo, woven labels, and care tags in both English and simple Yoruba phrases add meaning. Photography should show hands, vats, and reveals. Use kraft or recycled packaging with a short card on the craft’s origin, and credit Yoruba Adire tradition clearly.

SALES CHANNELS: WHERE YOUR INDIGO FINDS ITS PEOPLE

- Craft fairs and African arts festivals

- Etsy or Shopify for controlled storytelling

- Instagram and TikTok reels for process hooks

- Boutique wholesale and interior designers for stable orders

Pilot two channels first, then expand.

CONTENT THAT CONVERTS: WHAT TO POST

- Behind-the-scenes dip videos

- Pattern reveals in natural light

- Short lessons on motif meanings

- Styling tips for scarves and table settings

- Customer features with care tips

Always end with a clear call to shop, preorder, or join the list.

LAUNCH STRATEGY: BUILD DEMAND BEFORE SUPPLY

Create a limited capsule with 12 to 24 units, show swatches, take preorders for two weeks, and set a ship date. Use a waitlist when items sell out. Scarcity is strongest when it is true and you share your production calendar openly.

SCALING SMART: FROM SOLO TO SMALL STUDIO

- Batch dyeing by recipe, not by vibe, so color stays consistent

- Apprentices, paid fairly, trained in one technique at a time

- Inventory system with SKU codes by motif, base cloth, and dip count

- Production calendar with dye days, wash days, sew days, and photo days

Growth is discipline. Keep your signature, document every change, never rush the vat.

SUSTAINABILITY WINS: MAKE BLUE AND KEEP WATER BLUE

- Choose natural indigo or low-tox synthetic routes where possible

- Reuse water for first rinses, capture sediment, and dispose responsibly

- Upcycle offcuts into coaster

s, scrunchies, and patch kits

- Use plant-based detergents and recyclable packaging

Small studios can be cleaner than factories, make that a selling point with proof.

LEGAL AND ETHICS: STAY SAFE, STAY FAIR

- Attribution: credit Yoruba Adire in product pages and labels

- Permissions: avoid sacred symbols without guidance. Commission Yoruba artists when in doubt

- Trademark: register your brand name and logo

- Labels: comply with local rules, for example the U.S. FTC Care Labeling Rule. Include fiber content and country of origin

SAMPLE PROFIT PLAN: 20 SCARVES, REAL NUMBERS

Assume 20 cotton scarves, 55 dollars retail each.

Per scarf estimated costs:

- Fabric, 3.00

- Indigo and chemicals, 1.00

- Cassava paste and consumables, 0.50

- Thread, raffia, needles, 0.25

- Labels and packaging, 0.70

- Overhead allocation, 1.00

- Labor, 30 minutes at 12 dollars per hour, 6.00

Total per scarf, 12.45

Totals:

- COGS for 20, about 249.00

- Retail revenue, 1,100.00

- Gross profit before tax, about 851.00

Reinvest 40 percent into fabric and dye stock, 20 percent into marketing, 10 percent into tools, and save a buffer for two months of overhead.

Wholesale option:

- Price at 28 dollars, margin still healthy if you reduce labor per unit with batch work and keep quality constant.

ACTION CHECKLIST: WEEK-BY-WEEK PLAN

Week 1

- Research motifs, build mood board, source cotton and indigo, set up workspace

- Scour fabric and prepare test swatches

Week 2

- Practice Oniko and Alabere on swatches, test Eleko paste thickness, document results

- Choose three hero motifs and one geometric fold pattern

Week 3

- Build vat, stabilize pH, run controlled dip-oxidize tests

- Shoot behind-the-scenes content, open email waitlist

Week 4

- Produce first capsule, 12 to 24 units

- Quality control, care labels, pricing finalized

Week 5

- Photograph products on models and at home, write listings with motif meanings and provenance

- Launch preorder, share daily process clips, answer questions

Week 6

- Fulfill orders, request reviews, pitch two boutiques with a lookbook

- Debrief, refine recipes, plan next capsule with one new motif

A FINAL HUMAN NOTE

In Abeokuta, an elder dyer once said, you cannot rush the sky from green to blue. The cloth must breathe. That patience is your business edge. You are not selling a print, you are selling time, touch, and a responsible relationship to culture.

Ready to put your hands in the vat and build a brand that pays respect and pays your bills?

SOURCES AND FURTHER READING

- British Museum, Adire cloth collections, collection.britishmuseum.org

- Victoria and Albert Museum, Adire textiles overview, vam.ac.uk

- Jenny Balfour-Paul, Indigo, Egyptian Mummies to Blue Jeans, British Museum Press

- John Picton and Rayda Becker, African Textiles, Looms, Weaving and Design, Trustees of the British Museum

- Smithsonian National Museum of African Art, Indigo-dyed textiles, africa.si.edu

- Interviews and features on Nike Davies-Okundaye, BBC and The Guardian Nigeria

- Michel Garcia, Natural Dyeing and Indigo Vats, instructional lectures and videos