The Art of Tie & Dye: Step-by-Step Guide to Creativity and Profit

The Art of Tie & Dye: Step-by-Step Guide to Creativity and Profit

The Art of Tie & Dye: Step-by-Step Guide to Creativity and Profit

Introduction: Why Tie & Dye is More Than Just Fashion

Tie and dye travels with a story in its pocket. In West Africa, resist dye traditions like Yoruba adire, Sierra Leonean gara, Senegalese thioub, and Ghanaian batik grew from communities that learned to make color into currency, and cloth into testimony. Colonial mills tried to drown the market with factory prints. Yet women at dye pits in Abeokuta, traders in Freetown, and artisans in Saint-Louis answered with skill and stubbornness. They built cooperatives, reworked patterns, and turned local knowledge into survival strategies. That history still matters. When you twist a shirt and pour on pigment, you take part in a continental economy of creativity, one that outlasted tariffs, taxes, and imported trends.

Unlike our earlier deep dives into electoral coalitions and the cocoa-to-chocolate value chain, this guide is not about policy architecture. This is hands-on craft, a studio on your table, a small business that can start with a bucket and a brave idea. We will move from tools to technique, then into branding and profit, always with one eye on the past and the other on the next drop of dye.

Tools & Materials Needed

Start lean, but buy smart. Good tools protect your colors and your profit.

- Fabrics

- Cotton, rayon, linen for fiber reactive dyes. Silk and wool for acid dyes. Avoid polyester unless you have disperse dyes and high heat.

- Dyes and auxiliaries

- Fiber reactive dyes for plant fibers.

- Soda ash for fixing fiber reactive dyes.

- Urea to keep fabric moist in arid climates, optional.

- Sodium alginate or starch paste to thicken dye for detailed painting, optional.

- For natural dye paths, indigo leaves or cake, calcium hydroxide, and a reducing agent like fructose.

- Tools

- Buckets, squeeze bottles, ladles, stirring sticks.

- Rubber bands, twine, raffia, clamps, marbles or small stones.

- Needles and strong thread for stitch-resist, also called tritik in some traditions.

- Wax and a canting tool if you want batik resist.

- Safety

- Nitrile gloves, dust mask when handling dye powder, apron, eye protection.

- Ventilation for bleach or indigo vats.

- Workspace

- Plastic table cover, drying rack or clothesline, clear labeling for dye colors.

Tip, music in the background helps. So does a notebook. Record recipes, times, and what went wrong. The logbook becomes your silent mentor.

Step 1: Preparing the Fabric

Color keeps its promises when the fabric is clean.

- Pre-wash

- Hot wash your fabric with a small amount of detergent to remove factory sizing and oils. Do not use fabric softener.

- Scour for maximum absorbency

- For heavy cotton, simmer in water with a teaspoon of soda ash and a drop of dish soap for 30 to 60 minutes. Rinse well.

- Pre-soak for fiber reactive dyes

- Mix soda ash presoak. Common ratio is 1 cup soda ash per 1 gallon of water. Soak fabric for 15 minutes, wring gently. Keep it damp, not dripping.

- Mark lightly

- If precision matters, use washable pencil to sketch where a spiral will sit or where borders should fall.

In traditional adire eleko, artisans paint cassava starch paste onto cloth to create the resist. In stitch-resist, rows of small running stitches are pulled tight to form folds that block dye. Each path begins with clean cloth and clear intention.

Step 2: Tying Techniques, Spiral, Stripes, Sunburst, and More

Tie and dye is choreography. The folds and knots decide the rhythm, the dye follows the beat.

- Spiral

- Pinch the center point of your fabric. Twist until you get a flat disk with pizza-like pleats. Secure with three crossing rubber bands to create six sections. Each wedge can hold a different color.

- Stripes, accordion fold

- Fold the fabric back and forth into a narrow strip. Bind tightly at intervals using rubber bands or string. For diagonal stripes, fold at an angle.

- Sunburst with pebbles

- Place a small pebble or bead under the fabric. Pinch and tie a tight knot with a rubber band. Repeat across the cloth. Each tied bump resists dye to form rings.

- Crumple

- Scrunch fabric loosely into a mound. Place it on a rack. Apply dye from different angles. The randomness produces cloud textures.

- Stitch-resist, tritik

- Draw your pattern in chalk. Use needle and strong thread to sew parallel lines. Pull the thread to gather the fabric into tight ridges. The stitches create crisp, traditional motifs that read as heritage and quality.

- Clamp resist, itajime style adaptation

- Fold the cloth into a square. Sandwich it between two shapes, like wooden triangles or squares. Clamp tightly. Dip in dye. The clamped areas resist and form bold geometry.

- Rope wrap, arashi inspired

- Wrap fabric around a wide pipe or bottle. Spiral string around it, compressing the fabric. Dip or pour dye along the tube.

Hint, test small swatches. Five minutes of sampling can save a full day of rework.

Step 3: Mixing and Applying the Dyes

Pigment without discipline ends in heartbreak. Measure and respect the chemistry.

- Mix stock solutions

- For fiber reactive powders, dissolve in warm water. Start with 10 to 20 grams of dye per liter for medium to deep shades. Strain through a nylon to avoid clumps. Label.

- Apply light to dark

- Lay down lighter colors first. Follow with darker shades. Where they overlap, you create third colors. Leave some white space. Eyes need rest.

- Control saturation

- For sharp patterns, squeeze dye into folds with the bottle tip. For soft blends, drip from above and let capillaries do the work. Use thickened dye for painting fine lines.

- Natural indigo path, basic overview

- Prepare the vat with indigo, an alkali, and a reduction agent. The liquid looks yellow-green. Dip the tied fabric, then expose to air. It oxidizes to deep blue. Repeat dips for depth, rest between dips.

- Time matters

- Let the dye react. For fiber reactive on cotton, keep it damp and warm for 12 to 24 hours. For acid dyes on silk, heat gently as instructed by the manufacturer.

Safety notes, do not inhale dye powder. Do not mix bleach with ammonia or acid. Rinse spills quickly and label all containers.

Step 4: Drying and Fixing the Colors

Fixation is the difference between fade-out and heirloom.

- Fiber reactive dyes on cotton

- After curing damp for 12 to 24 hours, rinse in cold water until nearly clear. Then wash hot with a dye-safe detergent. Rinse again.

- Indigo

- After the last dip and oxidation, gently rinse in cool water. Cure for a day before the first wash to let the color settle.

- Acid dyes on silk or wool

- Follow heat set instructions. Usually a warm bath with a mild acid like vinegar, then thorough rinse.

- Sunlight

- Avoid full sun during curing. Heat fixes some dyes, but UV can distort others. Shade is your friend.

- Quality check

- Rub test. Place a white cloth on the dyed fabric and rub. If it stains, keep rinsing and washing.

Hang on a line or lay flat on a rack. Photographs your best pieces in good light for your catalog the moment they dry.

A Human Story: Hawa’s Hill, Freetown

Hawa lives above Kissy Road where the hill burns in the dry season and sings in the wet. Her mother taught her gara when she was fifteen. Stones wrapped in fabric, thread tight as a promise. In 2017, Hawa lost her stall. Construction crews moved the market boundary and a distributor from abroad flooded the lane with cheap prints. She started again with a plastic bucket, a cracked mirror, and a borrowed phone.

“I will not beg the color,” she said, laughing softly as she tied a sunburst. “The color must come to me because I tied it well.”

She built a routine. Monday is prep. Tuesday is blue, indigo and a late lunch. Wednesday is for cutting threads, the great reveal. Thursdays she photographs her work against a concrete wall that faces the harbor. Every caption told a story. “Cloth for mothers whose names are wind.” “Pattern for the girl who learned to wait.” Orders came slow, then faster. A boutique in Dakar sent a message. A buyer in Atlanta asked for wholesale. She hired two apprentices and started a savings club. The hill still scorches and sings. Her cloth sells.

That is what craft can do, not charity, not miracle, just skill, patience, and a market.

Creative Variations: Adding Patterns and Modern Twists

Your signature emerges at the edges, the little choices that build a brand.

- Resist paste artwork

- Try cassava starch or rice paste to paint symbols, like adire eleko. Let the paste dry, dye, then wash out the paste to reveal white motifs.

- Batik overlays

- Use a mix of beeswax and paraffin. Draw lines, dye, remove wax, repeat with new colors. Layered batik with tie and dye produces depth.

- Discharge patterns

- On dark cotton, apply diluted bleach or discharge paste with a brush or stencil to lift color. Neutralize with hydrogen peroxide solution, then rinse.

- Ice dyeing

- Cover crumpled fabric with ice, sprinkle dye powder. As it melts, dye migrates in veins. Great for abstract looks.

- Ombre dip

- Dip one end repeatedly, lifting slowly to build a gradient.

- S

creen printing and block printing

- Print Adinkra symbols or Nsibidi forms using fabric ink on top of your tie and dye base.

- Sustainable choices

- Test natural dyes like kola nut, onion skins, hibiscus, and sorghum. Not all are washfast, so run trials and document.

Remember, modern twist does not mean forgetful. Reference old motifs with respect. Name your pieces in languages that honor your customers and mentors.

How to Turn Your Tie & Dye Into a Business

A craft becomes a business when you know your numbers, your story, and your channel.

- Define your offer

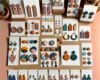

- Core products. Scarves, tees, wraps, yardage for tailors, cushion covers. Start with three to five SKU families to focus your brand.

- Limited editions. Seasonal drops keep your audience returning.

- Cost your work

- Track fabric price per meter, dye and chemical cost per piece, utilities, packaging, labor hours, rent or stall fees, transaction fees. Use a simple spreadsheet.

- Quality standards

- Set washfastness and color consistency thresholds. Keep recipes and SOPs. Train every helper with a checklist.

Production tip, plan in batches. Dye in color families to reduce waste. Standardize bottling and labeling of dye stocks.

Pricing, Marketing, and Selling Online & Offline

Price with clarity. Market with honesty. Sell where your customers actually buy.

Pricing models

- Keystone retail

- Retail price equals roughly two times your total cost. Adjust for craft premium and brand equity.

- Cost plus time

- Materials plus hourly labor rate plus overhead, then add profit margin. Example for a cotton scarf.

- Fabric and dye, 4.50 dollars

- Auxiliaries and utilities, 0.80 dollars

- Packaging, 0.70 dollars

- Labor, 1.5 hours at 6 dollars per hour, 9 dollars

- Overhead allocation per piece, 1 dollar

- Total cost, 16 dollars. Retail at 32 to 40 dollars depending on market and brand strength.

- Wholesale structure

- Wholesale price is usually 50 to 60 percent of retail. Set minimum order quantities, lead times, and payment terms. Common terms are 50 percent deposit, 50 percent at dispatch.

Marketing foundations

- Story and provenance

- Share your origin, your techniques, and your community. Buyers love heritage that is alive, not fossilized.

- Visual rhythm

- Clean photos, consistent backgrounds, detail shots of folds and edges. Show process and final piece.

- Content ideas

- Tutorials, studio diaries, customer features, care guides, and origin stories of motifs.

- Platforms

- Instagram Reels and TikTok for process videos. Etsy, Shopify, Jumia, Konga, Takealot for stores in different regions. WhatsApp Business for local orders and catalogs. Email lists for launches.

- SEO basics

- Use tags like tie-dye cotton scarf, indigo wrap, adire handmade fabric, Sierra Leone gara cloth. Write product descriptions that mention fiber content, size, wash care, and story keywords.

Offline channels

- Markets and fairs

- Lekki Arts and Crafts Market in Lagos, Accra Arts Center, Maasai Market in Nairobi, Marché Kermel in Dakar, neighborhood pop-ups. Ask for booth placement near natural light.

- Partnerships

- Tailors, fashion schools, and diaspora boutiques. Offer consignment only if the store is reputable and transparent.

- Corporate and event orders

- Custom wraps, staff gifts, or conference swag. Add logos with block printing or labels.

Brand protection and compliance

- Labels and care

- Include fiber content, country of origin, and washing instructions. Help customers avoid bleeding colors.

- IP and design protection

- Register your brand name and logo locally. Watermark certain images online. Document original patterns and dates.

- Export basics

- Research HS codes for your goods. Cotton woven fabrics often fall under 5208 or similar. Finished garments vary, like 6109 for knit cotton T-shirts. Explore AGOA for the United States, EU GSP, and AfCFTA for intra-African trade.

- Logistics

- Reliable couriers, moisture barriers in packaging, clear invoices. Factor shipping into your pricing, or offer separate rates.

Engagement script

- A simple DM reply

- “Thank you for your message. This scarf is hand dyed on cotton, 180 by 50 centimeters. It ships in 3 days. Care is cold wash, gentle soap. Price is 35 dollars or 23,000 naira. Would you like a short video to see the texture in sunlight.”

Sustainability, Water, and Work

Creative economies need more than applause. They need clean water, fair hours, and apprenticeships.

- Water management

- Reuse rinse water for first washes. Neutralize discharge dye baths. Do not pour hot dye slurries into drains.

- Safer chemistry

- Wear gloves and masks. Switch to low salt or low impact dye systems when possible. Test plant dyes, but demand washfastness before selling.

- People and pay

- Pay apprentices on time. Add a learning stipend. Create simple profit sharing for collections.

- Community

- Join cooperatives. Pool resources for shared dye vats or a local finishing laundry. Apply for grants aimed at creative SMEs.

Economic truth, sustainability protects your margins. Less waste, fewer customer returns, higher trust.

Strategy Corner: How This Piece Complements Our Other Topics

Previous pieces pressed into politics, cultural exports, and the macro forces that shape African markets. This guide flips the lens to micro enterprise. Small hands, repeatable processes, and brand storytelling. Different angle, same mission, build capacity and dignity inside the creative economy.

Common Pitfalls and How to Avoid Them

- Muddy colors

- Too many hues meeting in one fold. Use a color w

heel. Keep complements from colliding unless you want browns.

- Bleeding after wash

- Incomplete fixation or poor rinsing. Increase curing time. Use proper soda ash levels. Wash hot with a dye-specific detergent.

- Uneven patterns

- Inconsistent tying pressure. Practice. Use uniform bands and tension.

- Cracked batik lines

- Wax too brittle. Adjust beeswax to paraffin ratio. Warm fabric to keep wax flexible.

- Customer complaints about size or feel

- Standardize measurements and pre-wash to control shrinkage. Include care cards.

From Workshop to Brand: The Long View

The fashion world can be noisy. Hype burns hot and gone. Resist the rush. Build a brand that lives beyond a trend cycle.

- Signature

- Choose three motifs that are uniquely yours. Repeat them across products. Signature does not mean repetition without growth, it means recognizable authenticity.

- Collaborations

- Work with photographers, poets, and designers. A capsule with a local tailor can double your audience.

- Education

- Teach workshops. The teacher is often the artist who gets the best commissions.

- Data

- Track which colors sell in which seasons. Keep a simple CRM. Ask for reviews. Reward repeat buyers.

- Finance

- Separate business and personal accounts. Pay yourself a salary. Save for tax. Reinvest in tools that save time.

Humble truth, a brand is a set of promises you keep, week after week.

Case Study Mini, Abeokuta’s Dye Pits and the Politics of Cloth

In the 1940s, the adire trade faced a storm. Imported prints undercut local cloth, taxes squeezed market women, and colonial policy ignored artisan voices. The Abeokuta Women’s Union rose with organizers like Funmilayo Ransome-Kuti. They rallied, negotiated, and demanded fairer conditions. The lesson for today’s tie and dye entrepreneurs is sharp. Organize. Push for market infrastructure, clean water access, and fair permits. Creativity grows in communities that defend their rights.

Quick Start Checklist

- Wash and scour fabric.

- Pre-soak in soda ash if using fiber reactive dyes.

- Choose a pattern and tie tight.

- Mix dye carefully, label bottles.

- Apply light to dark, keep some white space.

- Cure in warmth, keep damp.

- Rinse cold, then wash hot, dry in shade.

- Photograph, price, and tell the story.

- Pack with care and send on time.

- Record every step for repeatability.

Conclusion: Building a Sustainable Artistic Brand

Tie and dye is technique, yes. It is also testimony. It connects you to indigo vats in Mali, to cassava paste tables in Abeokuta, to diaspora boutiques in London and Atlanta that carry a spark of home on a rack. It is a way to work with your hands and your history at the same time. The profit is not only cash in a ledger. It is agency. It is a skill you can teach to a cousin, a neighbor, a student who needs one clean idea to start a life.

What would change in your community if ten people mastered one pattern each, then sold it well for a year?

Sources and Further Reading

- Byfield, Judith. The Great Upheaval, Women and Nation in Postwar Abeokuta, Indiana University Press, 2003.

- Barbour, Jane, and Doig Simmonds. Adire Cloth in Nigeria, Institute of African Studies, University of Ife, 1971.

- Renne, Elisha P. Cloth That Does Not Die, The Meaning of Cloth in Bunu Social Life, University of Washington Press, 1995.

- British Museum Collection Online, Adire textiles, object records and essays, britishmuseum.org.

- Smithsonian National Museum of African Art, Indigo and textile traditions of West Africa, africa.si.edu.

- UNESCO, Re|Shaping Policies for Creativity, 2022 Global Report, unesco.org.

- UNCTAD, Creative Economy Outlook, Trends in international trade in creative industries, unctad.org.

- United States Trade Representative, African Growth and Opportunity Act, ustr.gov.

- CDC NIOSH, Working With Dyes and Chemicals, safety guidelines, cdc.gov/niosh.

Continue for printable recipes, a pricing worksheet, and five ready-to-post product captions.