The Art of Tie & Dye: Step-by-Step Guide to Creativity and Profit

The Art of Tie & Dye: Step-by-Step Guide to Creativity and Profit

The Art of Tie & Dye: Step-by-Step Guide to Creativity and Profit

Introduction: Why Tie & Dye Is More Than Just Fashion

Tie and dye is not just a craft. It is a language of resistance, a coded prayer, and a business plan rolled into color. Across Africa, patterns have spoken in whispers and in chants. Adire in Abeokuta carried the fingerprints of Yoruba women who turned cotton into identity. Indigo pits in Kano kept time with centuries of trade, migration, and craft guilds. In Mali, dyers taught patience, because true blue only arrives after breath and oxidization.

This is not a romantic detour. Colonial economies tried to break these circles of knowing by flooding markets with cheap prints and controlling cotton routes. Yet the dye persisted. People adapted. Today, tie and dye stands at a new crossroads, where craft meets e-commerce, where backyard vats meet global design briefs. If you want a guide that respects the past, embraces the present, and aims for profit, this is it.

Compared to earlier explorations on textile politics and the symbolism of woven cloth, this piece is practical, gritty, and studio focused. You will walk away with recipes, steps, and a market strategy you can test this week.

Tools & Materials Needed

Choose quality tools. Good inputs save you from muddy colors and wasted time.

- Fabric: 100 percent cotton is the workhorse. Rayon drapes beautifully. Silk is luxurious, treat it gently. Pre-washed, no sizing.

- Dyes: Fiber reactive dyes for plant fibers, Procion MX is popular. Natural indigo for heritage blues. Acid dyes for silk and wool.

- Auxiliaries: Soda ash for fiber reactive dyes, urea for moisture retention, salt to drive dye into fiber, thiourea dioxide or fructose for indigo vat reduction, vinegar or citric acid for acid dyes.

- Tools: Buckets, squeeze bottles, measuring spoons, wooden sticks, gloves, masks, aprons, plastic sheeting, rubber bands, twine, bulldog clips.

- Resist aids: Pebbles, beans, rope, raffia, clothespins, wax if you cross over into batik, cassava starch paste for stenciled resist.

- Cleaning and finishing: Mild detergent, sodium bicarbonate to neutralize bleach if you do discharge, cold and hot water access, drying rack, iron or heat press.

Step 1: Preparing the Fabric

Prep is everything. Dye bonds with clean fibers. Dirt, oils, and sizing create barriers.

- Scour: Wash fabric in hot water with a teaspoon of detergent and a pinch of soda ash. Rinse thoroughly.

- Soak: For fiber reactive work, mix 1 cup soda ash per 4 liters of warm water. Soak fabric 15 to 30 minutes. Wring without rinsing.

- Wet or dry: Some techniques like spiral benefit from slightly damp fabric. Stitch resist can be easier on dry fabric. Test both and note differences.

Pro tip: Label your buckets and keep a notebook. The best dyers are good historians of their own process.

Step 2: Tying Techniques, Spiral, Stripes, Sunburst, and More

Pattern is a choreography of compression and flow. The tighter the bind, the whiter the resist. The looser the bind, the more feathery the bleed.

- Spiral: Lay fabric flat. Pinch the center. Twist into a tight disk. Secure with three to six bands, making wedges like a pizza. Apply different colors in alternating wedges for contrast.

- Stripes, pleat and bind: Accordion fold the fabric. Bind at intervals. For neat pinstripes, stack folds tightly and bind evenly. For bolder bands, vary the spacing and tension.

- Sunburst, pebble and wrap: Place a small pebble or bean inside the fabric. Pinch and wrap with string. Repeat across the piece. Dots become constellations.

- Crumple: Scrunch fabric into a loose mound. Secure with a few bands. Apply dye lightly from above. This makes organic marbling.

- Stitch resist, tritik and oniko: Use needle and thread to create running stitches. Pull tight to gather. This technique, used across West Africa, yields delicate veining and controlled motifs.

- Starch resist, adire eleko: Mix cassava starch paste. Apply with stencils or freehand. Let dry. Dye, then wash out paste to reveal designs.

Cultural note: Yoruba adire oniko uses raffia tie points that birth starry fields. In Kano, narrow strip cloth and deep indigo create architectural depth. Learn the vocabulary, then add your accent.

Step 3: Mixing and Applying the Dyes

Accuracy makes color sing. Guesswork makes mud.

Fiber Reactive Dyes, cotton and rayon:

- Solution: In a bottle, dissolve dye powder in warm water. Add urea if your climate is dry. Wear a mask and gloves when handling powders.

- Salt push: In a bucket, dissolve non-iodized salt in warm water. Salt helps drive dye into the fiber.

- Application: After tying, place the fabric on a rack over a tray. Apply dye with squeeze bottles. Saturate folds. Do not overmix complementary colors right next to each other, they can turn brown.

Natural Indigo, cotton and rayon:

- Vat setup: Prepare a reduced indigo vat using thiourea dioxide or a fruit sugar method. Aim for pH around 10 to 11. The vat should look yellow-green on top with a coppery sheen.

- Dip and air: Dip the fabric slowly. Lift. Watch green turn to blue as oxygen meets dye. Repeat dips for depth. Allow 10 to 20 minutes between dips.

- Care: Do not stir air into the vat. Skim the flower on top gently.

Silk with Acid Dyes:

- Bath method: Heat water gently with dye and a bit of vinegar. Keep below boiling. Stir slowly to avoid spotty uptake. Rinse cool.

Test swatches before you commit. Photograph your mixes with labels. Build your own color library.

Step 4: Drying and Fixing the Colors

Lock in the work. Rushing this stage erases your effort.

- Batch time for fiber reactive: Wrap dyed pieces in plastic. Keep warm, 6 to 24 hours. Heat accelerates bonding.

- Rinse routine: Rinse cold to remove loose dye. Then wash hot with detergent until water runs clear. Rinse again.

- Neutralize discharge: If you used bleach for reverse dye, neutralize with sodium thiosulfate or a commercial bleach stop. Rinse deeply.

- Indigo finishing: After final oxidization, wash gently with mild soap. Some crocking is normal at first. A second gentle wash reduces it.

- Heat setting: Silk and some synthetics benefit from a low iron or brief heat press to settle color.

Creative Variations: Adding Patterns and Modern Twists

Innovation respects tradition by expanding it.

- Reverse dye on dark fabrics: Sprinkle a paste of bleach gel in controlled zones on black cotton. Neutralize immediately after the color lifts.

- Overprinting: Layer block prints or screens on top of tie and dye grounds. Calabash stamps or laser cut stencils bridge craft and contemporary branding.

- Ombre dips: Create gradients by dipping progressively less fabric each time. Works beautifully for scarves and dresses.

- Metallic and botanical accents: Thin metallic textile paint for subtle shimmer. Eco print with leaves for ghostly silhouettes.

- Hybrid methods: Combine stitch resist with targeted spray dye. Or wax a motif, then crumpl

e dye the background.

Document each variation. Customers love to see process diaries and studio shots. Your behind the scenes is part of the product.

A Human Story: Iya Sade and the Market That Would Not Die

Abeokuta, late 1990s. The old adire stalls still stood, but the middle aisles had gone quiet. Imports had undercut prices, and tourists were thin. Iya Sade, a second-generation dyer, watched her mother’s patterns fade from memory. She refused to fold.

She started small. She taught two teenage girls stitch resist after school. She stitched late, her fingers cut by thread, her back stiff over the basin. Then she did a bold thing. She took a neighbor’s digital camera, borrowed for a naming ceremony, and photographed her pieces on a sunlit wall. She wrote short stories for each cloth. Stars over Ogun. Storm on the Benue. At a cybercafe, she uploaded them to a Facebook page with prices and her phone number.

Orders trickled, then climbed. A diaspora bride wanted bridesmaids in matching sunbursts. A boutique in Accra asked for 20 scarves monthly. She raised her rates, trained more girls, added a water recycling drum, and cut plastic waste by half. Ten years later, her stall thrummed again, not as a relic, but as a studio. Every cloth carried a note, part product, part manifesto. Made slowly. Paid fairly. Dyed with memory.

Her success was not an algorithm miracle. It was structure. Costing. Quality control. A story told with clarity. She did not wait for permission. She asked herself, what can I bind tight, then release into the world with color and pride.

How to Turn Your Tie & Dye Into a Business

Treat your craft like a studio, your studio like a company, and your company like a community.

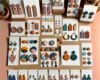

- Define your niche: Everyday basics, premium scarves, limited edition wall hangings, or uniforms for cultural events. Clarity helps marketing.

- Source ethically: Buy local cotton where possible. Build relationships with dye suppliers. Ask for MSDS sheets and safety guidance.

- Cost smart: COGS equals fabric plus dye plus auxiliaries plus labor plus utilities plus packaging. Add overhead and a profit margin. Write it down.

- Quality control: Standardize batching times, rinses, and drying. Create a defect bin and a seconds sale channel.

- Sustainability: Reuse rinse water for first washes. Capture and neutralize discharge fluids. Offer repair and re-dye services.

- Training: Build an apprenticeship path with fair pay. Craft grows when knowledge multiplies.

Packaging matters. Recyclable wraps, care cards, and a story card that links to a short video. People do not just buy color. They buy meaning.

Pricing, Marketing, and Selling Online & Offline

Price with a clear head. Market with a clear voice.

- Pricing models: Keystone retail is cost times two. Premium art pieces can go higher using value based pricing, especially with limited runs and signed labels.

- Product lines: Create tiers. Entry level scrunch tees. Mid tier scarves and totes. Signature collector pieces that release quarterly.

- Online: Instagram Reels, TikTok process clips, Shopify or WooCommerce store. List on Etsy for global reach and Jumia or Konga for regional.

- Offline: Pop ups, artisan fairs, fashion week fringe events, hotel concept stores, airport gift shops with ethical certifications.

- Content strategy: Show your hands at work. Explain a technique in 30 seconds. Drop a color recipe once a month to build authority.

- SEO and copy: Use terms like indigo scarf, adire cotton, hand dyed Lagos. Tell the story in 120 words per product page.

- Logistics: Weigh your items for accurate shipping. Use HS code 6214 for scarves and similar articles. Prepare simple care cards to reduce returns.

- Partnerships: Collaborate with photographers, stylists, and musicians for capsule drops. License a pattern to a stationery brand. Diversify revenue.

- Bookkeeping: Track cash flow weekly. Separate business and personal accounts. Pay yourself a salary, even if small.

The simplest growth hack is a happy customer. Ask for a photo wearing your piece. Share it. Offer a loyal customer discount that does not crush your margin.

continue

Troubleshooting: Common Problems and Fast Fixes

- Muddy colors: You mixed complements too closely

or oversaturated. Leave thin white buffers between color zones. Rinse thoroughly before overdyeing.

- Weak patterns: Your binds were loose. Use stronger twine or double wrap. Increase batching time.

- Indigo crocking: Too few oxidization cycles or overconcentrated vat. Shorter dips, more repeats, thorough washing after.

- Uneven dye on silk: Temperature spikes. Keep the bath stable and move the fabric gently.

- Colors fading in wash: Incomplete fixation. Increase batching time, correct soda ash concentration, and use a proper detergent.

Safety and Compliance

- Personal safety: Masks for powders, gloves for all wet work, ventilation in dye rooms.

- Waste: Neutralize discharge. Never pour strong bleach or high pH vats into drains without treatment. Consult local guidelines.

- Labels: Fiber content and care instructions are not optional if you plan to sell in formal retail.

Building a Sustainable Artistic Brand

Your brand is a social contract. It promises consistency, care, and cultural respect.

- Visual identity: A logo that works in black and white. A color palette inspired by your dyes. Clean product tags.

- Cultural integrity: Credit techniques and communities. If you borrow motifs, tell the lineage. Share profits through training or community projects.

- Documentation: Archive your patterns and dye notes. Future collections will thank you.

- Scale with soul: Add capacity without diluting quality. Train, do not just hire. Invest in better rinse systems and ergonomic stations before you buy a flashy sign.

This guide is different from earlier histories we explored. Those traced the politics of cotton fields and tariff walls. This one sits in the studio, sleeves rolled, hands blue. It connects the old vats to new customers with steps you can repeat and teach.

Conclusion: Building a Sustainable Artistic Brand

Tie and dye blends patience with risk. You compress cloth, trusting that the release will be beautiful. That is also how good businesses grow. Bind your costs. Bind your standards. Bind your story to a larger arc of African creativity that outlasted empire and imitators. Then release it to the market with courage.

What pattern are you ready to bind today, so you can unfold a future you want to live in?

Sources and Further Reading

- Smithsonian Center for Folklife and Cultural Heritage, articles on West African textile traditions and indigo practices.

- British Museum Collection Online, Adire textiles from Abeokuta, object histories and technique notes.

- UNESCO, documentation on traditional dye pits of Kano, Kofar Mata, and safeguarding intangible cultural heritage.

- UNCTAD, Creative Economy Outlook 2022, market data for craft and design exports.

- International Trade Centre, SheTrades resources for creative entrepreneurs and SME export readiness.

- Ruth Barnes, Textile traditions of Indonesia and Africa, comparative notes on resist dye methods, journal essays and museum catalogs.

- British Library, Endangered Archives Programme resources on Nigerian textile documentation.

- World Bank, Small and Medium Enterprise finance and market access reports relevant to creative industries.