Clay to Cash: Launch a Profitable Small‑Batch Pottery Brand from Your Kitchen Table

Clay to Cash: Launch a Profitable Small‑Batch Pottery Brand from Your Kitchen Table

Clay to Cash: Launch a Profitable Small‑Batch Pottery Brand from Your Kitchen Table

––––––––––––––––––––––––––––––––––––––––

Introduction: Clay remembers. Markets do too.

Clay carries fingerprints across time. From Nok terracottas unearthed in central Nigeria, to the red slip bowls of Nabeul in Tunisia, to the smoky black burnish of Zulu beer vessels, pottery has always been both vessel and story. In Africa, clay recorded ceremonies, kitchens, economies, and borders that moved without notice. So when I say pottery is a perfect small‑batch craft for a new creator, I am not speaking about a cute weekend project. I am talking about a living archive you can sell, at scale, from a kitchen table, in a world hungry for honest material.

We have already explored side hustles that scale in other craft worlds. Fashion capsules lean on tailoring and textiles. Food products, like micro roasteries, depend on import logistics and shelf life. Pottery is different. Margins are tight if you treat it as hobby output. Margins expand if you operate like a small factory with a soul. It is patient work that can be systemized. It is heritage you can modernize, and it is a path that aligns cultural pride with ecommerce reality.

This is a field guide, grounded in African tradition and global standards, built for the maker who wants to turn clay into cash, ethically and profitably.

––––––––––––––––––––––––––––––––––––––––

Why pottery is the perfect small‑batch craft for creators and side‑hustlers

- Repeatable forms. A mug or a bowl can be reproduced in consistent sizes with simple jigs, templates, and muscle memory. Consistency is the backbone of profit.

- High perceived value. Customers feel the weight of a handmade cup. Ceramic shapes carry presence that a printed tee does not.

- Durable inventory. Fired stoneware does not spoil. You can build stock for a launch, then restock in organized cycles.

- Branding baked in. Your maker’s mark, your glaze palette, your foot ring, all become instant brand identity.

- Global demand meets local story. The world wants tagines, pour‑over cones, incense burners, and dinnerware that speaks to a place. African design languages are already on mood boards. The difference is who gets paid.

Unlike content we have created about fast cycles in jewelry or seasonal skincare, pottery rewards a different pace. You build 30 mugs in a run, and you sell in drops. You do not chase micro trends. You create your own cadence, then invite customers into it.

––––––––––––––––––––––––––––––––––––––––

The minimalist studio setup: space, light, ventilation, and an efficient workflow map

You do not need a cavernous studio. You need zones.

- Zone 1, Clean bench. Clay prep, wedging, weighing. Keep it near a sink if possible. Cover surfaces with canvas or a vinyl mat.

- Zone 2, Wet work. Throwing on a wheel or handbuilding. Waterproof floor mat. A small table or banding wheel for handbuilders.

- Zone 3, Drying. Shelves that allow airflow. Avoid direct sun. Think slow and even.

- Zone 4, Dirty work. Trimming, sanding, recycling clay. This is where dust happens. Control it.

- Zone 5, Glaze corner. Buckets, scales, spray box if spraying, protective gear. Ventilation matters.

Light brings life to detail. Use indirect natural light for visual accuracy. If you only have evenings, warm LED work lamps reduce eye strain.

Ventilation is non‑negotiable, especially for glazing. A window fan, or portable extractor that vents outside, can protect your lungs. You are building a business that lasts. Build safety into the floor plan.

Map the workflow as a loop. Clay bag to wedging slab. Wet work. Shelf to dry. Trim table. Bisque boxes. Glaze corner. Firing queue. Photo corner. Pack station. Loop back. Less walking, less wasted motion, more throughput.

––––––––––––––––––––––––––––––––––––––––

Tools and materials checklist

Choose your path, wheel or handbuilding, or both.

- Clay bodies. Stoneware mid‑fire, cone 5 to 6, is a good balance of strength and accessible glazes. If you use a community kiln, ask what temperature they fire to. Test at least two clay bodies.

- Wheel vs handbuilding. A used kick wheel or small electric wheel is great, but not essential. Handbuilders produce iconic African forms every day. Slab, coil, pinch, press mold, all can be premium.

- Bats. Plastic or wood bats for moving thrown pieces. One per piece is ideal for speed.

- Ribs. Metal and rubber ribs for shaping and compressing.

- Trimming tools. Loop tools, needle tool, fettling knife.

- Calipers. For matching lids and consistent diameters.

- Scale. Digital kitchen scale for weighing clay and measuring glaze ingredients.

- Respirator. P100 or FFP3 for silica dust and glaze particles. Comfort matters, get one you will wear.

- Sponges, buckets, towels. Keep many, label glazing tools separate from clay tools.

- Maker’s mark. A custom stamp with your logo or initials for the base.

- Kiln access. Options include community studio, school, co‑op, or a small personal kiln if you have safe power and ventilation.

- Banding wheel. For handbuilding and trimming.

- Batts of canvas, rolling pin or slab roller substitute. If handbuilding, a simple wooden rolling pin and 2 ruler sticks as thickness guides can create consistent slabs.

- Measuring tools. Ruler, template cards, profile ribs for consistent forms.

––––––––––––––––––––––––––––––––––––––––

Safety first: silica dust control, wet cleaning, glazing ventilation, and PPE basics

Clay dust contains crystalline silica. Long exposure can scar lungs. You do not need to be scared. You do need a system.

- Wet clean only. Wipe with damp cloths. Mop, do not sweep. Vacuum only with a HEPA shop vac rated for fine dust.

- Control dry sanding. Better, avoid it. Smooth edges when the piece is leather hard with a damp sponge.

- Glazing ventilation. Use a fan in a window that pulls air out. If spraying, use a basic spray booth that vents outside and wear a P100 respirator.

- PPE basics. P100 or FFP3 respirator for dusty tasks. Safety glasses. Nitrile gloves if handling raw glaze materials. Closed shoes.

Reference local regulations for silica safety. Your lungs are the core tool of your business.

––––––––––––––––––––––––––––––––––––––––

Budget and startup costs: buy, thrift, borrow, or join a co‑op

You can start lean. Three sample budgets.

- $150 starter, handbuilding.

-

Clay, 25 kg. Basic stoneware.

-

Banding wheel or lazy Susan.

-

Rolling pin, thickness guides, cutting wire.

-

Basic tools, sponge, rib, needle, trimming loop.

-

Access to a community kiln. Pay per piece.

-

Respirator, entry level P100.

-

Total, about $150 if you source secondhand where possible.

-

$500 balanced kit.

-

Add used tabletop wheel or a sturdy used electric wheel if you find one.

-

More bats, 6 to 10.

-

Shelving unit for drying.

-

Scale, decent digital.

-

Starter glazes, 2 to 3 commercial dipping glazes, and a bucket.

-

Total, around $500 with careful thrift and co‑op access.

-

$1,500 small studio.

-

Reliable used wheel.

-

More bats, 12 to 20.

-

HEPA shop vac.

-

Expanded glaze set with materials to mix your own.

-

Photography corner, lights and backdrops.

-

Rental at a co‑op for kiln use or firebox fees.

-

You may add a small kiln if your space allows safe wiring and ventilation, but often co‑ops are smarter early on.

Buy new where it touches your body and lungs. Buy used where it is metal or plastic. Borrow or rent kiln space until your volume makes firing at home sensible.

––––––––––––––––––––––––––––––––––––––––

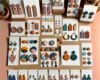

Brand story and niche: pick 1 to 2 hero forms and a signature glaze palette

Do not launch with everything from noodle bowls to planters. Focus builds both brand and process efficiency.

- Choose hero forms. Mug and bowl. Or bud vase and tray. Your choice should reflect your story. A North African inspired tagine lid silhouette as a bud vase profile can be a signature. An Ethiopian jebena curve can inspire a pour‑over.

- Signature glaze palette. Three colors maximum at launch. Choose glazes that photograph cleanly. Matte white, satin charcoal, a warm iron speckle. Or an indigo slip with a clear glaze, echoing indigo dye traditions. Test in different light.

- Visual language. Your stamp, your foot ring shape, the way your handle meets the belly, these become a brand the way a label does for fashion.

Root your brand in a story you can tell quickly. A line like, Small‑batch stoneware inspired by Sahel silhouettes, made slow at my kitchen table in Dakar, says more than a paragraph.

––––––––––––––––––––––––––––––––––––––––

Clay prep: reclaim, wedge, and moisture management

Consistency is quality.

- Reclaim. Save trimmings and slop. Dry them on a plaster slab or absorbent board. Rehydrate with water. Wedge back in. This cuts costs and smooths stress.

- Wedge. Spiral wedge or ram’s head wedge. Aim for even moisture and no air pockets. Two to five minutes per lump changes your throwing day.

- Moisture. Store clay in plastic, double bagged if possible. If too soft, lay it out on plaster. If too hard, wrap in a damp towel and seal.

––––––––––––––––––––––––––––––––––––––––

Throwing 101: center, open, pull, and shape

The path to a sellable mug and bowl.

- Center. Weigh 350 to 450 g for a mug, 500 to 700 g for a cereal bowl. Cone up and down to align particles. Keep elbow braced.

- Open. Press thumbs or fingers to open the center. Leave a 1 cm base for mugs, 0.8 cm for bowls. Use a needle tool to check depth.

- Pull. Two to three steady pulls. Slow wheel. Inside and outside hands work together. Compress the rim each time.

- Shape. For a mug, a gentle vertical cylinder with a slight inward collar at the rim. For a bowl, open curve, no sharp angle at the base. Use a rib to compress the interior bottom to reduce S‑cracks.

- Timing. Cut off and move to a bat when form is stable. Cover loosely with plastic to slow drying. Trim at soft leather hard.

Target times that keep your batch consistent. A mug form in 5 to 7 minutes, a bowl in 6 to 8. It is not a race. It is a rhythm.

––––––––––––––––––––––––––––––––––––––––

Handbuilding path: slab and coil techniques for mugs, trays, and bud vases

No wheel, no problem.

- Slabs. Roll to 6 to 7 mm thickness. Use a template for mug walls and base. Score and slip joins. Compress seams with a rib. Add a coil at the interior seam for strength.

- Coils. Build small vases with coils smoothed inside for strength. Compress every coil. Set forms over simple molds, like a bottle, to guide a silhouette.

- Trays. Use a plaster or wood mold. Drape slab. Cut and fold corners with slip and score. Add an accent rim.

Handbuilt pieces often hold a soulful line. Customers feel that.

––––––––––––––––––––––––––––––––––––––––

Trimming and handles: foot rings, ergonomic pulls, and timing

- Timing. Trim when leather hard, not floppy, not bone dry. Your finger should leave a slight dent but not stick.

- Foot ring. Center the piece on a bat. Trim a ring that leaves a stable base. Compress with a soft rib. Add your stamp now.

- Handles. Pull handles from a strip of clay or make lugs and attach. Aim for a single finger gap between knuckles and the mug. Score and slip both surfaces. Support from inside during attachment. Blend and compress joins.

- Edge finishing. Soften rims and handle edges with a damp sponge. No sharp edges. No excuses.

––––––––––––––––––––––––––––––––––––––––

Surface design: slips, underglaze, sgraffito, mishima inlay, wax‑resist logos

- Slips. Colored slip applied at leather hard gives depth. Use a contrasting slip band to frame a logo.

- Underglaze. Paint motifs inspired by Kente geometry, Ndebele patterns, or Amazigh symbols. Keep it respectful and research, then adapt into your own language.

- Sgraffito. Lay slip or underglaze, then carve through to clay. Works beautifully on red stoneware.

- Mishima. Inlay fine lines with colored slip into incised lines.

- Wax resist. Stamp your logo with wax, then glaze. The logo will reveal clay beneath.

Add a maker’s mark stamp on the foot. It is your signature and your guarantee.

––––––––––––––––––––––––––––––––––––––––

Drying and bisque firing: even drying, test tiles, avoiding S‑cracks, community kiln etiquette

- Even drying. Cover pieces lightly with plastic for the first 24 hours. Flip bowls on rims when safe to dry bottoms.

- Avoid S‑cracks. Compress bases while throwing and trimming. Do not overwork the center. Dry slowly.

- Test tiles. Make small tiles from each c

lay and glaze combo. Fire with every batch to monitor kiln behavior.

- Bisque. Standard bisque at cone 06 to 04. Label your pieces with initials and a kiln log.

- Kiln etiquette. Wipe bottoms free of glaze. Load neatly. Respect the tech. Offer to help load. Pay on time.

Community kilns are social capital. Treat them well. They will carry you through your launch.

––––––––––––––––––––––––––––––––––––––––

Glazing like a pro: specific gravity, application methods, witness cones, defects and fixes

- Specific gravity. Measure the density of your glaze with a scale and graduated cylinder. Target ranges vary, often 1.45 to 1.55 for dipping glazes. Note it in a log.

- Dipping vs pouring vs spraying. Dipping gives consistency. Pour interiors, dip exteriors. Spraying needs ventilation and a spray box, but produces subtle gradients.

- Layering. Test combinations on tiles. Two coats matte white, one coat iron speckle, may break beautifully on rims.

- Witness cones. Place witness cones to verify kiln temperature. Do not trust only the controller.

- Common defects.

- Pinholes. Often from dust or overfiring. Wipe bisque, strain glaze, adjust firing soak.

- Crazing. Glaze too tight on clay. Adjust recipe or choose a better fit.

- Shivering. Glaze flakes off, too low expansion. Change glaze.

- Leakers. Check bottoms and pinholes. Test with boiling water.

- Blisters. Fire slower or hold at peak to smooth.

Write everything down. Your glaze book is your map.

––––––––––––––––––––––––––––––––––––––––

Quality control: weight, wobble, glaze fit, and stress tests

- Weight. Aim for repeatable weights. Mug, 280 to 360 g. Bowl, 350 to 500 g. Customers do not want bricks.

- Wobble. Check flatness on glass. Wobble is a return risk waiting to happen.

- Lip test. Sip water from each mug to confirm comfort. You sell the mouthfeel as much as the look.

- Thermal shock. Pour boiling water into a mug preheated with warm water. Avoid cold to boiling jumps. Listen for pings. If it pings, revise your clay and glaze fit.

Reject ruthlessly. Reputation grows from what you do not sell.

––––––––––––––––––––––––––––––––––––––––

Photography that sells: natural light, clean backgrounds, and short‑form video

- Natural light. Shoot near a window with indirect light. Use white foam boards to bounce shadows.

- Backgrounds. Neutral, textured surfaces, like linen or lightly grained wood. Avoid busy patterns.

- Scale cues. Include a hand holding the mug, a spoon, or coffee beans. Online buyers need size cues.

- Lifestyle vs product. Do both. Product shots for the shop. Lifestyle shots for Instagram and pinboards.

- Short video. Show trimming curls falling, glaze dip reveals, or a handle pull. Thirty seconds. Music optional. Words minimal.

Your images bridge the gap between your kitchen table and a buyer’s screen in Nairobi, Lagos, Kigali, or London.

––––––––––––––––––––––––––––––––––––––––

Pricing with confidence: costing formula, wholesale reality, and drops

- Formula. Materials plus time plus overhead plus margin. Example. Mug materials, $1.80 clay and glaze. Time, 25 minutes total across making stages at $18 per hour, $7.50. Overhead per piece, shelves, electricity, kiln fees, $2.00. Base cost, $11.30. Retail double to triple, $28 to $36. Choose a number you can say out loud without blinking.

- Wholesale keystone. Wholesale is often half retail. You must price retail to sustain that. If you retail at $30, wholesale at $15, your base cost must be under $7 to make sense, or you create a separate wholesale line with simpler finishes.

- Price ladder. Offer three steps, entry coaster or incense holder, mid mug, hero bowl or vase. Never trap all your value at one price point.

- Limited drops and preorders. Sell in batches. Preorder slots can fund materials. Be clear on lead times.

Confidence is math plus narrative. Know your numbers. Then tell your story.

––––––––––––––––––––––––––––––––––––––––

Sales channels: Instagram Shop, Etsy, your own site, markets, wholesale, corporate gifting

- Instagram Shop. Tag products. Post reels of process to increase reach. Link to a Shopify or other simple site.

- Etsy. Good for discovery if your SEO and photos are strong. Treat it like a mall kiosk, not your flagship.

- Your own site. The brand home. Collect emails. Host your launch drops here.

- Markets. Choose curated markets with buyers who understand handmade pricing. Bring a small display that feels like your brand.

- Wholesale pitch email template.

Subject: Small‑batch stoneware for your shelves, [Shop Name]

Hi [Buyer Name],

I am [Your Name], a ceramic artist working from my kitchen studio in [City]. I make small‑batch stoneware, inspired by [regional influence], with a clean palette that photographs beautifully.

I have a line of [hero forms], retailing at [price range], with lead times of [weeks]. I can offer wholesale at [terms], minimum [units or value]. Photos and a line sheet are attached, plus a link to short process videos.

I would love to send a sample mug and discuss a small trial order for your next reset.

Warmly,

[Name]

[Site]

[Instagram]

[Phone]

- Corporate gifting bundles. Offer 20 to 200 units, stamped with a company logo via wax resist or decal. Package with a care card and optional coffee or tea from a local roaster as a bundle.

––––––––––––––––––––––––––––––––––––––––

Packaging and shipping: eco materials, double‑boxing, and breakage policy

- Box. Double box ceramics. Inner box snug with paper. Outer box 5 cm clearance with cushioning.

- Void fill. Recycled paper, corrugated wraps, compostable peanuts if needed. Avoid plastic where possible. Use tape that holds in humidity.

- Care cards. Include use and care, dishwasher and microwave guidance, plus your story.

- Shipping calculators. Use online platforms that compare carriers and rates. Print labels at home. Offer flat rate for simplicity, or real time rates for transparency.

- Breakage policy. Replace on first report with photo evidence. Insure larger orders. Price a small spoilage rate into your margin.

The unboxing is a marketing moment. Treat it like a storefront.

––––––––––––––––––––––––––––––––––––––––

14‑day launch plan: production calendar, batch sizes, drop strategy

Day 1 to 2, finalize forms. Make templates. Decide palette.

Day 3 to 6, produce first batch. Aim for 24 mugs and 18 bowls, or your chosen mix. Label each piece.

Day 7, trim and add handles. Stamp bases.

Day 8 to 9, slow dry and sand lightly with a damp sponge.

Day 10, bisque fire at a community kiln. Load test tiles.

Day 11, glaze. Record specific gravity and dip times.

Day 12, glaze fire. Place witness cones.

Day 13, quality check. Photograph. Write listings and captions. Prep email newsletter.

Day 14, launch drop. Limit quantity. Offer preorders for next batch with a 3 to 4 week lead time. Engage on social, answer questions, collect feedback.

Restock cadence, every two to three weeks. That rhythm keeps scarcity honest and production sane.

––––––––––––––––––––––––––––––––––––––––

Upsells and recurring revenue: commissions, workshops, digital goods, and a mug‑club

- Commissions. Offer custom initials, a house mug for a cafe, or wedding sets. Price for time and disruption to your fl

ow.

- Workshops. Host a 2 hour handbuilding session for 8 people. Fire and deliver finished pieces. Charge per seat. Community centers and cafes love this.

- Digital templates. Sell PDF templates for slab mugs, handle profiles, and glaze record sheets.

- Glaze recipe PDFs. Once you develop a safe, consistent recipe, sell it with firing schedules and photos of results.

- Mug‑club subscription. Quarterly delivery of a limited palette mug. Include a short story card that connects the design to a specific African motif or historical note.

Recurring revenue is your oxygen between drops.

––––––––––––––––––––––––––––––––––––––––

A human story: Amina’s kitchen table, Lagos Island

Amina grew up on Lagos Island near Campos. Her grandmother sold akara in bowls that had a certain whisper when you stacked them. They were thrown by a woman from Abeokuta who had learned from her own mother. Then the factory bowls came, cheap and bright. The whisper faded.

In 2020, Amina lost a catering job. She watched clips of potters trimming foot rings on her phone and saw something she recognized. A rhythm. She took a bus to a community studio in Yaba, bought five kilos of clay, and sat under a fan with women making water filters and students making ashtrays. The studio tech, a quiet man who knew kilns like other men know engines, taught her to wedge. A week later she pulled a handle that looked like a question mark. Then another that looked like a promise.

She made twenty mugs in a month, all different. She sold seven to a friend who owned a cafe in Surulere. She priced too low and packed them too casually. Two arrived chipped. She refunded, then learned to double box. She asked her uncle, a mason, to cut her a plaster slab. She started reclaiming clay. She learned to say no when a buyer asked for a discount that would put her below cost. She set her palette, one white, one indigo, one iron brown, and stuck to it.

When she stamped the base with a small crescent mark her grandmother used to carve on wooden spoons, orders began to feel like messages sent back. In month six, she pitched a wholesale order to a design shop that sells books and baskets by local makers. They took twelve mugs. Six months later they took sixty. She hired her cousin to help with packaging, paid her daily, and taught her to check rims with a coin.

It is not a fairytale. Power cuts delay firings. glaze batches sometimes go weird in harmattan. But the whisper is back. When she stacks a dozen bowls and they settle into each other without wobble, the stack makes a sound like a yes.

––––––––––––––––––––––––––––––––––––––––

Africa’s ceramic memory, and what you are building on

Before shipping containers, clay traveled on heads and donkeys. Potters across the continent fired with pit kilns and bonfires that could reach earthenware temperatures. Kingdoms marked clay with their stories. Ife heads in terracotta reimagined the human face with a seriousness the museum glass cannot mute. Moroccan potters at Safi turned the sea into color through copper and cobalt. Nubian communities along the Nile tempered clay with chaff and burnished bowls that felt like river stones.

Colonial extraction systems rewired those circuits. Workshops were folded into export factories or left to decline. Museums took sculptures without consent. Yet ceramics persisted in kitchens and markets. Today, community studios in Accra, Dakar, Johannesburg, Nairobi, and beyond are building a new bridge. Your kitchen brand is part of a return that is not nostalgic. It is commercial, assertive, and still intimate.

Tell that truth in your About page. Your mug is part utility, part inheritance, and part ambition to keep skilled work visible and paid.

––––––––––––––––––––––––––––––––––––––––

Final thoughts

Clay rewards those who respect process. Business rewards those who respect customers and their own time. Africa’s ceramic lineage reminds us that craft is also politics. Who gets paid for the beauty everyone posts on their feeds. When you launch from your kitchen table, you are not only building a brand. You are placing your hands on a rope that stretches across centuries and pulling it toward a future where craft labor is dignified and documented.

What will your first hero form say about you, your city, and the people you want sitting at your table?

––––––––––––––––––––––––––––––––––––––––

Sources and further reading

- The Metropolitan Museum of Art, Timeline of Art History, Nigerian Nok Terracotta. https://www.metmuseum.org/toah/hd/nok/hd_nok.htm

- British Museum, Art of Ife. https://www.britishmuseum.org/collection/galleries/ife

- UNESCO, Traditional knowledge of pottery making in Safi, Morocco. https://ich.unesco.org

- Ceramic Arts Network, Beginner guides and technical articles on throwing, trimming, and glazing. https://ceramicartsnetwork.org

- Digitalfire, Glaze chemistry, defects, and material data. https://digitalfire.com

- The Orton Ceramic Foundation, Pyrometric cones and firing. https://www.ortonceramic.com

- NIOSH, Crystalline silica exposure, controls and respirators. https://www.cdc.gov/niosh/topics/silica

- HSE UK, Control of exposure to silica dust. https://www.hse.gov.uk

- Victoria and Albert Museum, Ceramics of North Africa and the Middle East, overviews and images. https://www.vam.ac.uk

- FAO and UN reports on craft livelihoods in Africa, market access and small enterprise development. https://www.fao.org, https://www.un.org

Continue